Since defects induce laser damage, and defects are randomly distributed in optical components, the detection and evaluation of laser damage performance of optical components has become another important research content. The standard for laser damage threshold testing was established in the 1990s and has been continuously improved with the development of laser technology and optical materials. The international standard ISO21254 for laser damage threshold testing uses a sampling method, which has the problems of large measurement uncertainty, mismatch between off-line test results and the application effect of components in high-power laser systems. The reason is that the laser beam might not able to accurately capture the randomly distributed defects. For the large-aperture optical components of ICF, the raster scanning test method solves the problem of missing defects through a similar exhaustive method. At the same time, it also adopts the classification evaluation of optical component damage, and proposes a concept of functional damage threshold for practical applications.

The proposal of the functional damage threshold provides another idea for the high-throughput operation of large-aperture optical components, that is, to tolerate defects and a certain degree of damage, which is a practical choice for large-scale laser projects. Based on this, a series of post-processing technologies independent of the traditional manufacturing process of optical components have been developed to remove a small amount of defects remaining in the manufacturing process or suppress the thermodynamic response of these defects under laser irradiation, including laser pretreatment of dielectric films, laser pretreatment of DKDP crystal, chemical etching treatment of fused silica, repair by CO2 laser, etc. These post-processing techniques vary by component type, and each post-processing technique is selected based on the characteristics of a specific defect and its laser damage behavior, which still belongs to the scope of research on the root cause of laser damage.

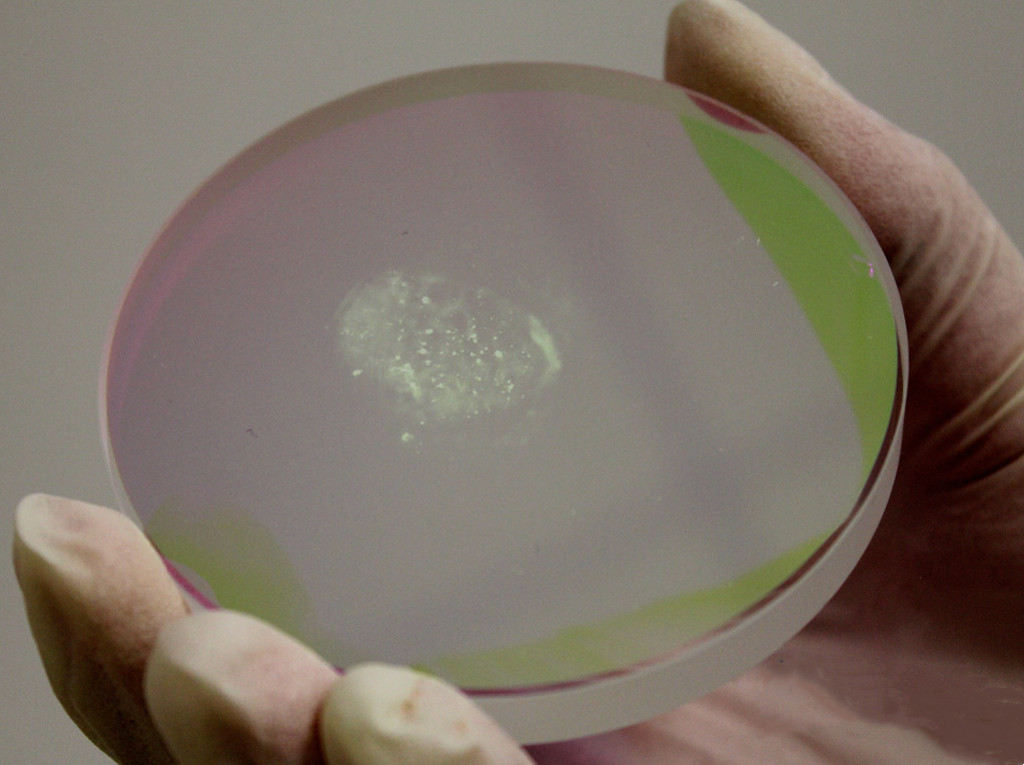

We will first introduce the nodular defect that induces damage to fundamental-frequency laser components with dielectric membrane. This is not only an important bottleneck problem for ICF laser drivers, but also a common problem for thin-film components used in laser applications in other fields. It is a typical microscopic defect, which can be characterized by conventional optical detection methods, so it is easy to establish a direct relationship between defects and induced damage, and it also lays the foundation for understanding the cause of its formation and seeking its control methods. Then, the problem of laser damage induced by nanoscale precursors in optical components will be introduced. Here, two types of optical components limited by nanoscale precursors are introduced: KDP-like crystals and multilayer dielectric films applied to picosecond pulses. Because its scale is much smaller than the optical resolution, and due to the lack of characterization techniques that can directly correlate with laser damage, it is difficult to trace this kind of damage to the morphology and even the cause of the defect, which is still a problem that still plagues researchers at this stage. Finally, aiming at the engineering application requirements of m-scale optical components in the ICF laser field, the raster scanning laser pretreatment technology and its evaluation method for removing or suppressing defects and improving the damage resistance of optical components will be introduced.

Post time: Jan-21-2023