3 The main application of lithium tantalate crystal

3.1 SAW Wave filter

There are many studies on filters in SAW devices. Wave filters have the advantages of low transmission loss, high reliability, great manufacturing flexibility, analog/digital compatibility, excellent frequency selection characteristics, and can realize a variety of complex functions. Materials used to make filters are generally required to have good surface flatness, high electromechanical coupling coefficient, small propagation loss, small temperature coefficient, good repeatability, high reliability, mass production, and low cost.

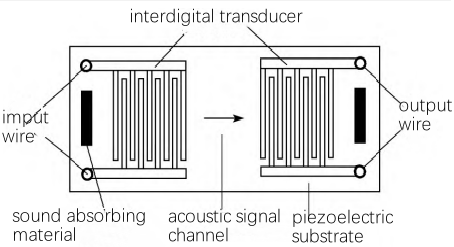

SAW filters can be divided into high-loss filters and low-loss filters according to insertion loss. They can be divided into transverse filters and resonator-type filters according to the structure and coupling method. Figure 2 is a schematic structural diagram of a horizontal SAW filter (SHSAW). When the input excitation electrical signal passes through the input end interdigital transducer, SAW is excited due to the inverse piezoelectric effect, and propagates on the piezoelectric substrate to reach the output interdigital transducer. At the same time, due to the piezoelectric effect, the SAW is excited by the output interdigital transducer. The device is then converted into an electrical signal for output, and filtering is implemented in the electro-acoustic and acoustic-electrio conversion process.

Figure 2. Structural diagram of transverse SAW filter

The materials currently used to prepare SAW filters mainly include quartz, lithium tantalate crystal, lithium niobate crystal (www.wisoptic.com), etc. Table 5 shows the main materials and their piezoelectric properties. As can be seen from the table, quartz has the lowest temperature coefficient and the best temperature stability. However, the electromechanical coupling coefficient of quartz is too low. When the operating frequency is too high, the achievable relative bandwidth range will drop sharply due to the influence of factors such as the bracket capacitance after the chip is assembled. So it is difficult for SAW filters made of quartz to achieve high frequencies and large bandwidths.

The electromechanical coupling coefficient of lithium tantalate and lithium niobate is higher than that of quartz. Lithium tantalate can achieve a relative bandwidth of 6% to 7%, while lithium niobate can achieve a relative bandwidth of 10% to 12%, but the temperature coefficients of lithium tantalate and lithium niobate are relatively high. X-cut lithium tantalate crystal has zero temperature cutting direction. By accurately controlling the cutting direction, the zero temperature coefficient point can be controlled within the room temperature range, so that it can be used to make high-frequency and large-bandwidth filters.

Table 5. SAW materials and their piezoelectric properties

|

Material |

Cutting Type |

Electromechanical Coupling Coefficient |

Temperature Coefficient (10-6/℃) |

|

Quartz |

AT |

0.09 |

0.2 |

|

Lithium Tantalate |

X |

0.44 |

5.0 |

|

42°Y |

0.51 |

17.0 |

|

|

128°Y |

0.52 |

22.0 |

|

|

Lithium Niobate |

X |

0.68 |

45.0 |

|

42°Y |

0.62 |

52.0 |

|

|

128°Y |

0.66 |

59.0 |

Post time: Nov-16-2023